TECHNOLOGY

Surface Modified Pigment Powder: Revolutionizing Performance and Efficiency

SURFACE MODIFIED PIGMENT POWDER

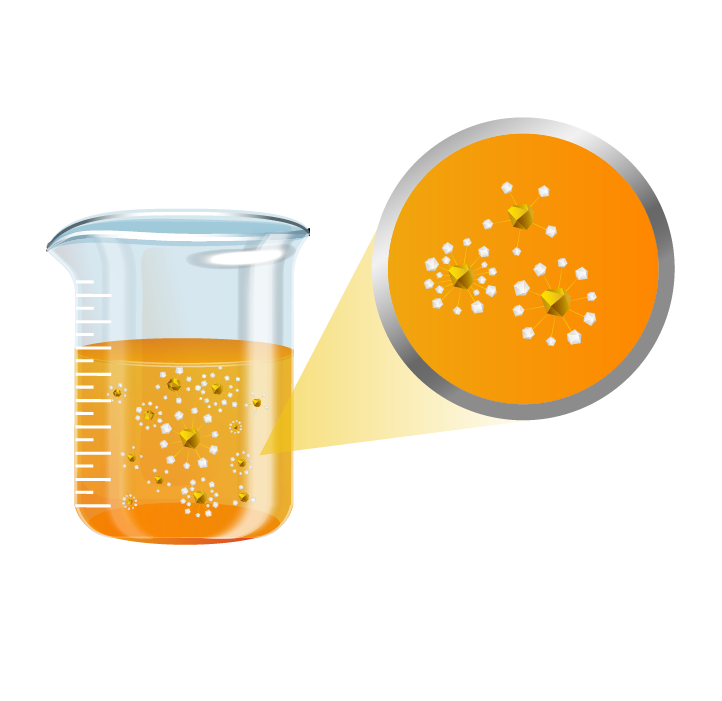

- Ionic groups on the pigment surface ensure exceptional stability.

- Dispersing groups are firmly bonded to the pigment surface.

- A diverse range of functional groups is available.

- Product range allows customization for specific system needs.

Surface Modified Pigment Powder: Revolutionizing Performance and Efficiency

Surface Modified Pigment Powder represents a significant advancement in inkjet pigment technology, offering exceptional benefits that cater to the needs of a wide range of industries. From coatings and printing to textiles and beyond, this innovative product is engineered to enhance productivity, quality, and cost-effectiveness.

1. Easy Handling and Storage

One of the standout features of Surface Modified Pigment Powder is its dry powder form. This makes it highly convenient for storage and transportation. Unlike liquid-based pigment concentrates that may require special handling or storage conditions, this powder ensures ease of use and logistical efficiency. It eliminates the risks of spillage or contamination during transit, providing a clean, hassle-free solution. The dry form also reduces the overall weight, reducing transportation costs and making it an economical choice for manufacturers and distributors alike.

2. Stable Quality and Long Shelf-Life

Surface Modified Pigment Powder is renowned for its consistent quality. The pigment powder retains its properties over an extended shelf-life with advanced processing and surface treatment techniques. This stability ensures manufacturers can rely on consistent results, even when the product is stored for long periods. The long shelf-life also reduces waste, making it an environmentally friendly option for businesses striving to minimize their ecological footprint.

3. Rapid Dissolution in Water Systems

Self-dispersed technology aligns perfectly with global sustainability standards. SDT reduces toxic waste and lowers the environmental burden by eliminating hazardous substances typically involved in pigment production. Its production process is designed to consume less energy and minimize waste, contributing to a reduced carbon footprint.

In terms of lifecycle, products made with SDT are easier to recycle due to their pure composition, which does not contain complex blends of chemicals. This aspect is particularly appealing in the circular economy, where the ability to recycle and reuse materials is paramount.

4. Exceptional Color Performance

Color quality is a critical factor in many industries, and Surface Modified Pigment Powder excels in this aspect. With its high color strength, excellent color density, gloss, and saturation(OD value), it produces vivid and striking results. The pigment’s excellent transparency allows for layering effects and intricate designs, making it ideal for applications that demand precision and creativity. Furthermore, its outstanding lightfastness ensures that the colors remain vibrant and resistant to fading, even under prolonged exposure to sunlight or harsh environmental conditions.

5. Superior Dispersibility

Achieving uniform dispersion is often a challenge in pigment applications, but this product easily overcomes that hurdle. The advanced surface modification of the pigment ensures superior dispersibility, allowing it to spread evenly within the medium. This eliminates clumping and streaking, ensuring a smooth and flawless finish. The even distribution of pigment particles also enhances the overall quality and appearance of the final product, making it highly desirable for premium applications.

6. High Pigment Content and Purity

Surface Modified Pigment Powder is formulated with a high pigment content and exceptional purity. This ensures that the colors produced are vibrant but also accurate and consistent. The high purity level minimizes impurities, reducing the likelihood of defects or variations in the final product. This level of precision is crucial in industries such as printing, where accurate color reproduction is a top priority.

7. Ultra-Fine Particle Size and Narrow Distribution

The pigment powder is characterized by its ultra-fine particle size and extremely narrow size distribution. This property enhances the smoothness and precision of the final application. Fine particles blend seamlessly into the medium, reducing the need for extensive grinding or processing. The uniform size distribution ensures consistent performance, further contributing to the overall efficiency and quality of the product.

8. Reduced Grinding Time and Labor Costs

One of the significant benefits of using Surface Modified Pigment Powder is the reduced grinding time. Its fine particle size and superior dispersibility eliminate the need for prolonged grinding processes, allowing manufacturers to achieve the desired consistency quickly. This accelerates production and reduces energy consumption and wear on equipment. Additionally, the streamlined process lowers labor costs, making it a cost-effective solution for businesses.

9. Excellent Compatibility with Dye-Grade Systems

Versatility is another key advantage of Surface Modified Pigment Powder. Its superior compatibility with dye-grade systems broadens its range of applications. This pigment powder integrates seamlessly, whether used in high-performance coatings, advanced printing systems, or textile dyes, delivering optimal results. This adaptability makes it a valuable asset for manufacturers seeking a multipurpose pigment solution.