TECHNOLOGY

ADVANCED SELF-DISPERSED TECHNOLOGY SURFACE MODIFIED

Introduction

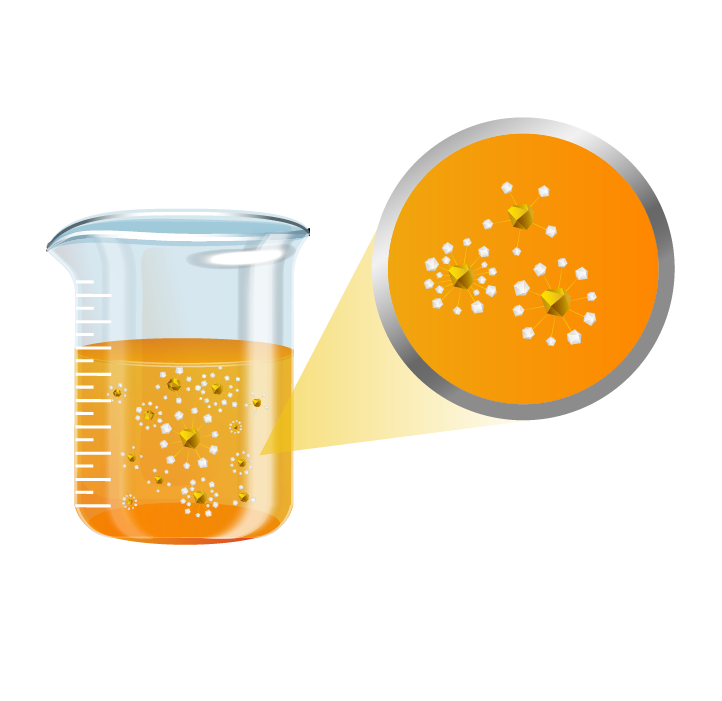

In a world increasingly driven by the pursuit of sustainability and efficiency, the materials science industry stands at the forefront of innovation, developing solutions that meet today’s needs and pave the way for a more sustainable future. One of the most transformative advancements in recent years has been the development of Self-Dispersed Technology (SDT). This technology is revolutionizing how colors are integrated into products, making waves across various industries due to its unique blend of efficiency, environmental friendliness, and unmatched quality.

Innovation in Particle Engineering

Self-dispersed technology features smaller particles, a significant leap forward in coloring agent technology. Traditionally, larger particles have been used, resulting in muted and less transparent colors. SDT, by utilizing nano-scale particles, enhances the color’s brightness and transparency dramatically. The physics behind this lies in how light interacts with the particles; smaller particles scatter light differently, resulting in a more vivid color perception.

Moreover, these smaller particles contribute to higher color strength, meaning less material is needed for the same impact, reducing the product’s overall material footprint. The reduced particle size also contributes to a lower viscosity of the mixtures, facilitating easier mixing and application. This feature particularly benefits automotive paints and printing industries, where application efficiency is critical.

Purity and Safety in Composition

A standout feature of SDT is its composition, which is devoid of common additives such as resins, abrasives, dispersants, or solvents. This purity dramatically reduces the risk of adverse reactions, which is especially important in products that come into close contact with humans, like cosmetics and clothing. Moreover, the absence of these chemicals simplifies the production process, reducing potential environmental contamination.

The technology’s non-toxic and odorless nature marks it as a superior choice for indoor applications, significantly reducing the VOC (Volatile Organic Compounds) emissions associated with paints and coatings. This feature not only improves the safety profile of the workplaces where it is used but also endears it to a market that is increasingly health-conscious.

Environmental Impact and Sustainability

Self-dispersed technology aligns perfectly with global sustainability standards. SDT reduces toxic waste and lowers the environmental burden by eliminating hazardous substances typically involved in pigment production. Its production process is designed to consume less energy and minimize waste, contributing to a reduced carbon footprint.

In terms of lifecycle, products made with SDT are easier to recycle due to their pure composition, which does not contain complex blends of chemicals. This aspect is particularly appealing in the circular economy, where the ability to recycle and reuse materials is paramount.

Stability and Quality Assurance

SDT offers exceptional stability, a crucial factor for manufacturers who require consistency in long production runs. This stability means that colors do not degrade over time or under high-stress conditions, such as exposure to sunlight or extreme temperatures. This is particularly important for outdoor applications like exterior paints and automotive finishes.

Quality assurance is another area where SDT shines. Manufacturers can rely on the consistently high quality of the pigments, which ensures that end products maintain uniformity in color and performance. This consistency is supported by rigorous quality control processes throughout the production and distribution phases, ensuring that every batch meets stringent standards.

Versatility and Applications

The versatility of Self-Dispersed Technology is one of its most significant benefits. Its applications range from industrial uses in automotive and aerospace manufacturing, where durability and precision are key, to consumer goods such as electronics, where aesthetic appeal and safety are paramount. Additionally, SDT is making inroads into the textiles industry, offering a non-toxic alternative for fabric dyes.

Innovative uses also abound in the arts, where the vivid colors and safety profile of SDT make it ideal for new forms of artistic expression. The technology’s adaptability also suggests future applications in emerging fields like biodegradable plastics and environmentally friendly packaging solutions.

Conclusion

Self-dispersed technology represents a paradigm shift in how industries think about color and coatings. With its myriad benefits—from enhanced aesthetic qualities to improved environmental and safety profiles—SDT is setting new standards in materials science. As industries seek solutions that combine efficiency with sustainability, technologies like SDT will play a pivotal role in shaping the future. For businesses, embracing this technology means gaining a competitive edge and contributing to a more sustainable planet. Stakeholders across the spectrum are encouraged to explore the opportunities presented by SDT, as it offers a path to innovation that aligns with economic and environmental goals.

Surface Modified Pigment Powder: Revolutionizing Performance and Efficiency

SURFACE MODIFIED PIGMENT POWDER

- Ionic groups on the pigment surface ensure exceptional stability.

- Dispersing groups are firmly bonded to the pigment surface.

- A diverse range of functional groups is available.

- Product range allows customization for specific system needs.

Surface Modified Pigment Powder: Revolutionizing Performance and Efficiency

Surface Modified Pigment Powder represents a significant advancement in inkjet pigment technology, offering exceptional benefits that cater to the needs of a wide range of industries. From coatings and printing to textiles and beyond, this innovative product is engineered to enhance productivity, quality, and cost-effectiveness.

1. Easy Handling and Storage

One of the standout features of Surface Modified Pigment Powder is its dry powder form. This makes it highly convenient for storage and transportation. Unlike liquid-based pigment concentrates that may require special handling or storage conditions, this powder ensures ease of use and logistical efficiency. It eliminates the risks of spillage or contamination during transit, providing a clean, hassle-free solution. The dry form also reduces the overall weight, reducing transportation costs and making it an economical choice for manufacturers and distributors alike.

2. Stable Quality and Long Shelf-Life

Surface Modified Pigment Powder is renowned for its consistent quality. The pigment powder retains its properties over an extended shelf-life with advanced processing and surface treatment techniques. This stability ensures manufacturers can rely on consistent results, even when the product is stored for long periods. The long shelf-life also reduces waste, making it an environmentally friendly option for businesses striving to minimize their ecological footprint.

3. Rapid Dissolution in Water Systems

Self-dispersed technology aligns perfectly with global sustainability standards. SDT reduces toxic waste and lowers the environmental burden by eliminating hazardous substances typically involved in pigment production. Its production process is designed to consume less energy and minimize waste, contributing to a reduced carbon footprint.

In terms of lifecycle, products made with SDT are easier to recycle due to their pure composition, which does not contain complex blends of chemicals. This aspect is particularly appealing in the circular economy, where the ability to recycle and reuse materials is paramount.

4. Exceptional Color Performance

Color quality is a critical factor in many industries, and Surface Modified Pigment Powder excels in this aspect. With its high color strength, excellent color density, gloss, and saturation(OD value), it produces vivid and striking results. The pigment’s excellent transparency allows for layering effects and intricate designs, making it ideal for applications that demand precision and creativity. Furthermore, its outstanding lightfastness ensures that the colors remain vibrant and resistant to fading, even under prolonged exposure to sunlight or harsh environmental conditions.

5. Superior Dispersibility

Achieving uniform dispersion is often a challenge in pigment applications, but this product easily overcomes that hurdle. The advanced surface modification of the pigment ensures superior dispersibility, allowing it to spread evenly within the medium. This eliminates clumping and streaking, ensuring a smooth and flawless finish. The even distribution of pigment particles also enhances the overall quality and appearance of the final product, making it highly desirable for premium applications.

6. High Pigment Content and Purity

Surface Modified Pigment Powder is formulated with a high pigment content and exceptional purity. This ensures that the colors produced are vibrant but also accurate and consistent. The high purity level minimizes impurities, reducing the likelihood of defects or variations in the final product. This level of precision is crucial in industries such as printing, where accurate color reproduction is a top priority.

7. Ultra-Fine Particle Size and Narrow Distribution

The pigment powder is characterized by its ultra-fine particle size and extremely narrow size distribution. This property enhances the smoothness and precision of the final application. Fine particles blend seamlessly into the medium, reducing the need for extensive grinding or processing. The uniform size distribution ensures consistent performance, further contributing to the overall efficiency and quality of the product.

8. Reduced Grinding Time and Labor Costs

One of the significant benefits of using Surface Modified Pigment Powder is the reduced grinding time. Its fine particle size and superior dispersibility eliminate the need for prolonged grinding processes, allowing manufacturers to achieve the desired consistency quickly. This accelerates production and reduces energy consumption and wear on equipment. Additionally, the streamlined process lowers labor costs, making it a cost-effective solution for businesses.

9. Excellent Compatibility with Dye-Grade Systems

Versatility is another key advantage of Surface Modified Pigment Powder. Its superior compatibility with dye-grade systems broadens its range of applications. This pigment powder integrates seamlessly, whether used in high-performance coatings, advanced printing systems, or textile dyes, delivering optimal results. This adaptability makes it a valuable asset for manufacturers seeking a multipurpose pigment solution.